Infrastructure

Our own manufacturing factory is equipped with cut to sew capacity of 30,000pcs per month..

Our Owned Infrastructure

Our manufacturing unit has hi-tech machines and highly experienced peoples to take care of sewing & packing process.Our Owned factory has 30 sewing machines & its corresponding supplements to undertake the cutting, sewing, ironing, packing process. Our machine details as follows

- Power Aided straight knife Cutting Machines

- Computerised automatic single needle sewing Machines

- Computerised automatic Flat lock & cover lock sewing Machines

- Computerised automatic ZIG ZAG sewing Machines

- Power assisted snap button machine

- Heat transfer label fusing machine

- Stain removing Machines

- Vacuum + Steam iron machines

- Washing machines + Tumble dryer to check fabric parameters

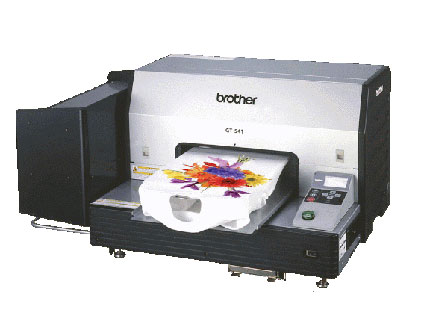

Infrastructure we are using with third parties

A well-planned and well knit infrastructure forms the backbone of our industry.In order to turn a fibre in to a fine apparel, being we are a small company, we are using the following infrastructure with our suppliers(third parties) on job work basis. Our team of merchandisers & quality controllers plays a vital role in supervising those works resulting our product has top notch quality(likewise it was manufacturered with our own facilities).

The below photos are for illustration purpose & we don’t won these facilities. But we are using these with our suppliers..

Our Team of Experts

In order to serve customer with low volumes, we had an adoring team of talents with sound exposure on products, we are glad that this team is our main infrastructure.

- Merchandising manager

- Senior Merchandisers

- Pattern & CAD makers

- Sample Merchandisers

- Embellishment Merchant (For Printing & Embroidery)

- Fabric Manger

- Fabric Quality Controllers

- Production Manager

- Production Quality Controllers

- Finishing In charge

- Logistics Manager